Rotomolding or rotational molding is a creative, innovative and versatile manufacturing process widely used to manufacture plastic hollow products. It is known for its ability to make complex shapes with excellent durability and uniform wall thickness.

Because of its unique features it becomes the preferred method for many industries for their products.

Selection of the right material is one of the crucial factor in the success of rotational molding process.

If this guide we will delves into common materials used in the rotomolding process along with different types (Most common polyethylene and other thermoplastic). It’s technical and mechanical properties, various applications and key processing consideration.

Table of Contents

ToggleIntroduction to Rotational Molding

History and Development

Rotational molding, first comes into existence in early 20th century and continue to evolve significantly over the last couple of decades. It was initially used to make hollow wax objects. As the time passes the process expanded and include the plastic in the 1940s.

The advancement of machinery and materials like polyethylene allow rotomolding process to because the mainstream manufacturing process.

Overview of the Rotomolding Process

Powder loading into Mould

A define amount of plastic powder (kgs/tons) is loaded into mold.

Heat and rotation of mold

The mold be heated in an oven in two axes. This will allowed powder to be melted and uniformly into the inner surface of the mold.

Cooling

The mold is gradually cooled with the help on cooling fans to solidifying plastics into desired shape.

Unloading

The mold will be open and finished product is taken out from mould.

Advantages of Rotomolding

Flexibility in Design

Rotomolding process allows for large product size and complex shapes.

Consistent wall thickness

It ensures uniform wall thickness with quality and strength

Cost effective method

Compare to other molding process it has lower initial investment cost.

Longevity

Product made from Rotomolding process are durable and stress free with excellent resistance.

Applications of Rotomolding

Agriculture

The Large Part of Rotational Moulding Application comes Agriculture Industries products like Plastic Water Storage Tanks, and Tractor Hood

Automotive

Another Application of Rotomoulding is automotive products such as Fuel Tanks, Air Ducts PE Sofa.

Consumer Goods

Rotomolding have expand its application range in Benches, Playground Equipment, Kayaks & Pots & Planters

Industrial

Industrial Products like CV Tanks, Spiral Tank, Capsule Tanks, Pallets, Loft Tank, Underground Tank, and Slim Tanks made through rotomolding process

Polyethylene (PE) Grades in Rotomolding

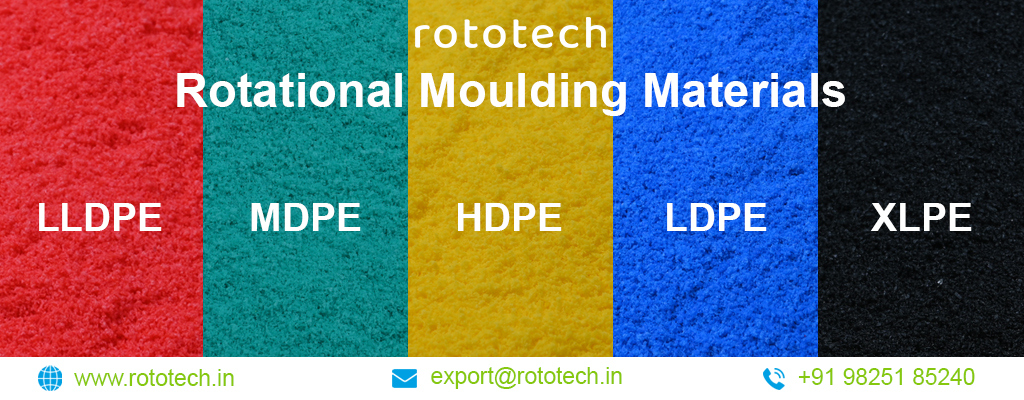

There are different types of PE materials used in Rotomolding process such as, LLDPE, MDPE, HDPE, LDPE and XLPE.

PE (Polyethylene) is most widely & commonly used materials in Rotomolding process because of its top notch excellence processing properties, easy availability & cost efficiency. There are several grades available in the market & be used based on end application & required characteristics of the products.

Linear Low Density Polyethylene (LLDPE)

Properties

- Good Impact Resistance

- High Flexibility

- Puncture Resistance

- Durable

- Good Strength

Applications

- Plastic Water Storage Tanks

- Containers

- Toys

- Recreational Equipment

Processing Benefits

- Lower Melting Points

- Shorter Cycle time

- Improved & Enhanced Production Efficiency

- Less Warpage

- Less Shrinkage

Medium Density Polyethylene (MDPE)

Properties

- Balance Rigidity

- Balance Flexibility

- Crack Resistance

- Impact Environmental Stress Cracking

- Higher Strength

- Moderate Density

Applications

- Fuel Tanks

- Shipping Constrainers

- Household Goods

Processing Benefits

- Easy Flow

- Suitable for Large & complex shapes

High Density Polyethylene (HDPE)

Properties

- High Strength High Density Ratio

- Tremendous Impact Resistance

- Chemical Resistance

- Great Weather ability

Applications

- Large Storage Tanks

- Outdoor Furniture

- Agriculture Products

Processing Benefits

- Light Weight

- No-Leaching

Low Density Polyethylene(LDPE)

Properties

- Highly Pliability

- Tough

- Good Impact Resistance

- Lower Tensile Strength

- Greater resilience.

Applications

- Squeeze Bottles

- Toys

- Flexible Hoses

Processing Benefits

- Low Melting Point

- High Flow Characteristics

- Easy To Process

Cross Linked Polyethylene (XLPE)

Properties

- Enhanced Chemical Resistance

- Thermal Stability

- Withstand High Temperatures

- Aggressive Chemicals

Applications

- Chemical Storage Tanks

- Fuel Tanks

- Piping Systems

Processing Benefits

- Optimal Material Performance

Other Rotomolding Materials

70% materials used in rational moulding are polyethylene & remaining 30% materials are of different such as EVA, PVC, Nylon, PC and PP.

EVA Co-polymer (EVA)

Properties

- Excellent Impact

- Stress-Crack Resistance

Applications

- Medical Devices

- Footwear

- Flexible Tubing

Processing Benefits

- Easily blended with other materials

- Enhance specific properties

- Good Flexibility

- Clarity,

- Soft Feel

Polyvinylchloride (PVC)

Properties

- Good Chemical Resistance

- Toughness,

- Durability

- Rigid

- Flexible

Applications

- Plumbing Components

- Medical products

- Flexible hoses

Processing Benefits

- Good Heat Stability

- Easy Processability

Nylon

Properties

- Thermal Resistance.

- Good Wear Resistance

- Chemical Stability

Applications

- Automotive Parts

- Industrial Components

- Consumer Goods

Processing Benefits

- High Strength

- Toughness

- Durability

- Performance

Polycarbonate (PC)

Properties

- High Impact Resistance

- Transparency,

- Dimensional Stability

Applications

- Optical Disks

- Eyewear Lenses

- Safety Helmets

Processing Benefits

- Withstand High Temperatures

- Flame-Retardant

Polypropylene (PP)

Properties

- High Chemical Resistance

- Fatigue Resistance

Applications

- Automotive Components

- Consumer Goods

- Food Containers

- Medical Devices

Processing Benefits

- Low Density.

- Resistant Solvents, Bases, and Acids

Material Selection Considerations

Selecting the right material for your rotational moulding process is on the crucial decision you have to take. Please consider the following points to ensure you get the desired products based on your required specification or performance.

Mechanical Properties

Selecting the right material for your rotational moulding process is on the crucial decision you have to take. Please consider the following points to ensure you get the desired products based on your required specification or performance.

Strength

Your selected materials should provide the good strength to the intended applications while selecting the strength of the products also considering points like adequate tensile, flexural strength & compressive.

Impact Resistance

Your selected materials essentially should have high impact resistance with good mechanical stress or potential impacts.

Flexibility

You should also consider flexibility & pliability in material selection. Materials having high elongation break are preferred.

Chemical Resistance

Environmental Exposure

Selected Material should endure exposure to various chemicals such as bases, acids, solvents & environmental pollutants.

Corrosion Resistance

Make sure selected materials should be corrosion resistance as it ensures excellent chemical stability.

Thermal Stability

Heat Resistance

Selected materials should withstand with heating & cooling cycle without degrading the properties.

Thermal Expansion

Selected materials should possess low thermal expansion properties which help to maintain dimensional stability at the time of temperature fluctuations.

Cost

Material Cost

The cost of materials directly proportional to quality of the intended products & it can also affects the performance of the products.

Processing Cost

Many times the manufacturer oversight the processing cost such as cycle time, energy consumption & potential waste.

Processing Ease

Powder Form

The selected materials should be easily pulverised into fine mesh powder for consistent & uniform heating & melting in the mold.

Flow Characteristics

Right Materials will ensure the good flow properties to avoid uneven distribution. It will also help in coating of the mold interior.

Cycle Time

The cycle time plays in important role; right materials will ensures you have shorter cycle time with improved production efficiency & will curtail the cost.

Advanced Topics in Rotomolding Materials

Innovations in Material Science

Innovation is the heart of any industry; rotational moulding is also not a exception in this category. With the continuous development in material science, it enables manufacturer to choose suitable materials for their end application. Following are the innovations.

Nanocomposites

By Incorporating nanoparticles into rotational moulding it will enhance mechanical properties, barrier performance and thermal stability.

Biodegradable Polymers

By developing eco friendly materials that easily decompose by reducing environmental impact.

Smart Polymers

R & D team must ensures for creating materials that responds to external stimuli like temperature, light (UV), pH, by offering new functionalities.

Sustainable and Recycled Materials

The Internal Environmental Law & global warming have push the materials manufacturer to think about the sustainability of the world to developed the recycled & bio based materials.

Recycled Polyethylene

It is very much essential to utilize the post consumer & post industrial recycled PE waste for environmental foot print.

Bio Based Polymers

Now its time to create less dependency on traditional based materials & creates renewable resources from corn starch or sugarcrane.

Future Trends and Developments

It’s always been fascinating to understand & know the emerging trends of rotomoulding materials based on performance enhancement & sustainability.

High Performance Polymers

Due to different demands of high performance materials it is essential to develop a material that consists of superior mechanical and thermal properties.

Additive Manufacturing Integration

It is essential to develop materials which can easily integrate with different additives such as UV, Anti Microbial, Anti Fungus, and Anti Algae.

Functional Coatings

Future of Rotomolding materials is widely appreciated & accepted by customer how the roto powder supplier brings some innovative ideas like advance coatings to enhance surface properties & improve the look & feel of products by incorporating the aesthetic version on it.

Case Studies and Real-World Applications

| Case Study 1 | Automotive Fuel Tanks |

|---|---|

| Material | High Density Polyethylene (HDPE) |

| Application | Fuel tanks for automobiles |

| Challenges | The need for high impact resistance, chemical resistance, and lightweight design. |

| Solution | HDPE was selected for its excellent mechanical properties and chemical stability. The material’s low density contributes to overall weight reduction, enhancing fuel efficiency. |

| Case Study 2 | Agricultural Storage Tanks |

|---|---|

| Material | Cross Linked Polyethylene (XLPE) |

| Application | Storage tanks for agricultural chemicals and water |

| Challenges | Exposure to harsh chemicals and varying environmental conditions. |

| Solution | XLPE was chosen for its superior chemical resistance and thermal stability. Its cross-linked structure provides durability under stress, ensuring long-term performance in harsh conditions. |

| Case Study 3 | Recreational Kayaks |

|---|---|

| Material | Linear Low Density Polyethylene (LLDPE) |

| Application | Kayaks for recreational use |

| Challenges | The need for high impact resistance, flexibility, and UV resistance. |

| Solution | LLDPE was selected for its excellent impact resistance and flexibility. UV stabilizers were added to the material to enhance weatherability, ensuring the kayaks’ durability and performance in outdoor environments. |

Conclusion

Rotational Moulding is a highly adaptable, flexible & well known manufacturing process from a variety of materials. Each mechanical & technical property has its unique offering & suited for specific applications. By having clear requirements in terms of characteristics, end applications & processing consideration of varied rotational moulding materials enable manufacturers to make the informed decision. It will also affect the end products durability & quality. Due to various Research & Development activities over the last couple of years helped material science to increase the range of materials & create a new opportunities for innovation & sustainability in rotomoulding industry.

In summary, whether it’s the flexibility of LLDPE, the strength of HDPE, or the chemical resistance of XLPE, each material offers distinct advantages that can be leveraged in the rotomolding process. By carefully selecting and optimizing materials, manufacturers can achieve the desired performance and quality in their products, driving success in various industries.

In Conclusion, different end application required different grade of materials for flexibility i.e. LLDPE Rotational Moulding Materials. For High Strength it would be HDPE Rotomoulding Materials & for Chemical Resistance it would be XLPE Rotational Rotomoulding Materials. By carefully selecting & optimized materials (through incorporating additives such as UV, Anti Microbial, Anti Fungal, Anti Algae, Aesthetics) can achieved desired performance & quality in products. One can bring revolutionize change in industries.