HDPE Rotomolding Powder

HDPE (High-Density Polyethylene) Rotomolding Powder is a specially formulated thermoplastic used in rotational molding (rotomolding) to create seamless, durable, and impact-resistant plastic products. It is known for its high strength-to-weight ratio, excellent chemical resistance, and UV stability, making it ideal for industrial, automotive, agricultural, and commercial applications.

HDPE Rotomolding Powder offers superior flow properties, uniform moldability, and fusion strength, ensuring consistent thickness and defect-free end products.

Rototech Inquiry Form

Rototech

| Property | Value / Range | Test Standard |

|---|---|---|

| Density | 0.935 – 0.945 g/cm³ | ASTM D1505 |

| Melt Flow Index (MFI) | 3 – 7 g/10 min | ASTM D1238 |

| Impact Strength | High | ASTM D256 |

| Tensile Strength | 20 – 27 MPa | ASTM D638 |

| Flexural Modulus | 800 – 1100 MPa | ASTM D790 |

| Vicat Softening Point | 120 – 130°C | ASTM D1525 |

| Heat Deflection Temp. | 70 – 85°C | ASTM D648 |

| UV Stability | Yes (UV-8, UV-12) | Accelerated Weathering Test |

| Chemical Resistance | Excellent | ASTM D543 |

Key Features of HDPE Rotomolding Powder

High Impact Strength

Resists cracks and stress fractures

Excellent Chemical & Corrosion Resistance

Suitable for fuel and chemical storage

UV-Stabilized Formulation

Prevents degradation in outdoor applications

Uniform Moldability & Fusion

Ensures seamless, defect-free plastic products

Lightweight Yet Rigid

Ideal for durable yet lightweight products

Custom Colors & Additives

Available in various grades to meet industry needs

Recyclable & Sustainable

Environmentally friendly and reusable

Applications of HDPE Rotomolding Powder

Industrial & Automotive Applications

Chemical & Water Storage Tanks – Leak-proof, corrosion-resistant solutions

Automotive Components – Fuel tanks, protective covers, fenders

Industrial Containers & Bins – Strong, lightweight, and durable

Outdoor & Recreational Applications

Playground & Sports Equipment – UV-resistant slides, modular play structures

Marine & Boating Solutions – Buoys, kayaks, floating docks

Agricultural Products – Irrigation tanks, compost bins, feed storage

Medical & Sanitary Applications

Sanitary Waste Bins – Non-toxic, easy-to-clean containers

Biohazard Disposal Units – Leak-proof and chemically resistant

Advantages of HDPE Rotomolding Powder

High Durability & Impact Resistance

Withstands harsh environments and rough handling

Uniform Thickness & Seamless Construction

No weak joints or stress points

UV & Weather Resistance

Ideal for outdoor applications like water tanks and playground equipment

Excellent Chemical Compatibility

Does not degrade with exposure to harsh chemicals

Cost-Effective Manufacturing

Reduces material wastage and tooling costs

Flexible Design Possibilities

Can be molded into complex shapes with intricate details

Environmentally Friendly

100% recyclable and sustainable

Disadvantages of HDPE Rotomolding Powder

Lower Heat Resistance Compared to Other Plastics

Not suitable for high-temperature applications

Limited Structural Rigidity for Large Loads

May require reinforcement for heavy-duty applications

Slower Processing Time

Rotomolding is slower than injection or blow molding

Initial Setup Cost

Custom molds may have a high initial investment

Why Choose Us for HDPE Rotomolding Powder?

Industry-Leading Quality & Certifications

We provide ISO & ASTM-certified HDPE powders, ensuring compliance with global quality standards.

Custom Formulations for Specific Applications

Our HDPE powders are available in standard, high-impact, UV-stabilized, and chemical-resistant grades, with custom colors and melt flow rates.

Bulk & Wholesale Supply at Competitive Prices

We cater to large-scale manufacturers, ensuring reliable bulk supply and cost-effective pricing.

Fast Global Shipping & Reliable Logistics

Our extensive distribution network ensures timely delivery across India and international markets.

Technical Support & Consultation

We offer expert guidance in selecting the right HDPE powder for your application needs.

Points to Consider While Purchasing HDPE Rotomolding Powder

Melt Flow Index (MFI)

Choose the appropriate MFI based on the complexity of your mold design.

UV Resistance

Opt for UV-stabilized grades for outdoor applications to prevent degradation.

Chemical Compatibility

Ensure the material is suitable for chemical storage and fuel tanks.

Impact Strength & Flexibility

Select the grade based on structural load requirements.

Color & Additives

Decide on custom colors, flame retardants, and reinforcement additives.

Supplier Reputation & Certifications

Buy from ISO-certified manufacturers with a proven track record.

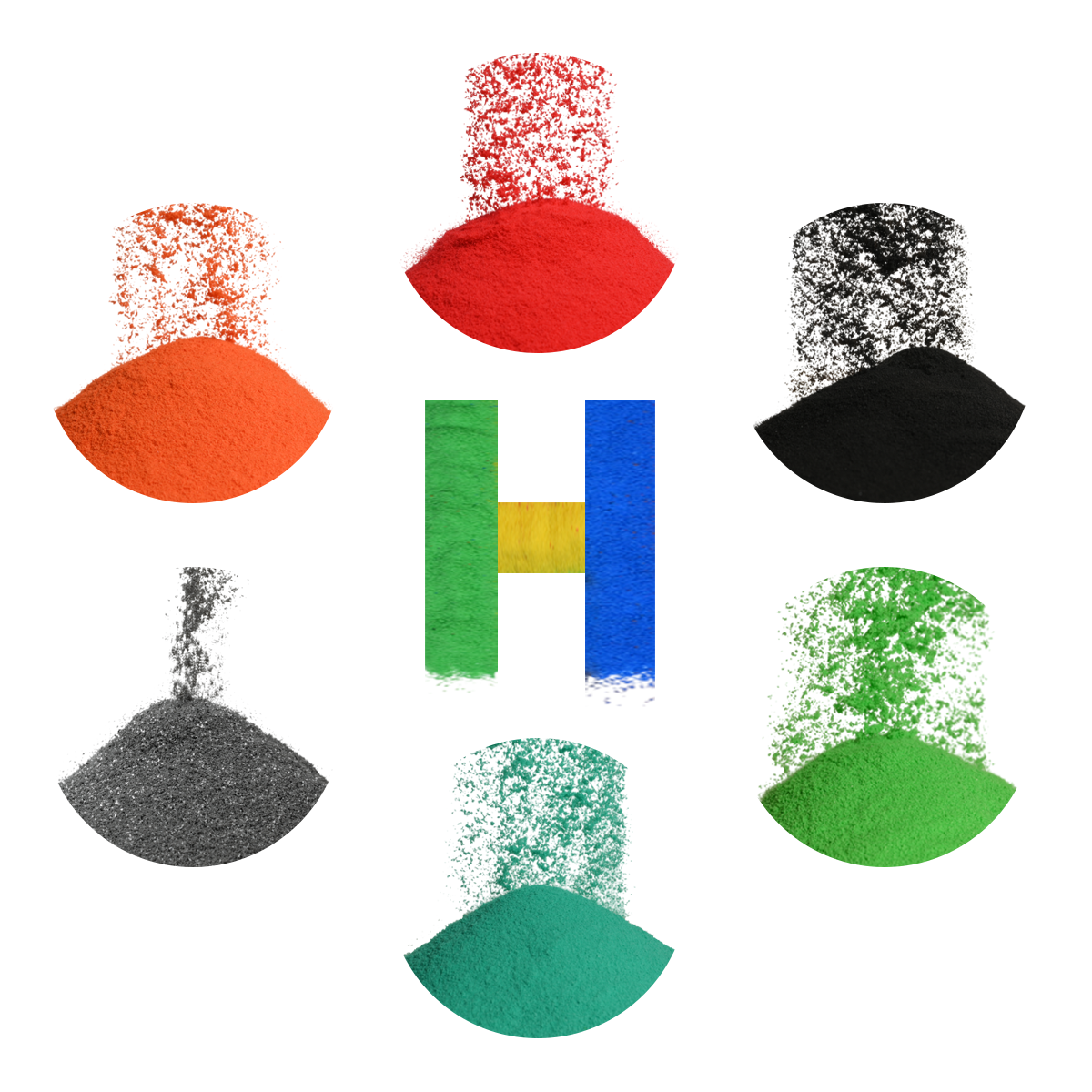

Available Colours

Note: We can also make the custom powder based on your requirements.

FAQs

What is HDPE Rotomolding Powder used for?

HDPE rotomolding powder is used in water tanks, fuel tanks, playground equipment, industrial bins, marine buoys, and medical containers due to its durability, impact resistance, and chemical stability.

Is HDPE rotomolding powder food-grade?

Yes, food-grade HDPE is BPA-free, non-toxic, and safe for potable water storage and food containers.

How does UV stabilization improve HDPE products?

UV stabilizers protect against sun exposure, preventing material degradation, discoloration, and brittleness, thereby extending product lifespan.

What is the difference between HDPE and LLDPE in rotomolding?

| Feature | HDPE Rotomolding Powder | LLDPE (Linear Low-Density Polyethylene) |

|---|---|---|

| Strength | High | Medium |

| Flexibility | Moderate | High |

| UV Resistance | Excellent | Good |

| Best For | Water tanks, industrial products | Soft, flexible applications |

Can HDPE rotomolding powder be recycled?

Yes, HDPE is 100% recyclable, making it a sustainable choice for plastic manufacturing.

What are the standard packaging options?

HDPE rotomolding powder is available in 25kg bags, 50kg bags, and jumbo bags (500kg – 1 ton).