LLDPE Rotomoulding Powder

LLDPE Powder is finely pulverized & processed material which is used in rotomoulding process to make the hollow products.

This is mostly used in thermoplastic polymers best known for excellent flexibility, very good impact strength and versatility.

This Raw Materials can be procured from the market from the reliable sources & then processed into machinery for fine mesh.

LLDPE Rotomoulding Powder is the core products of roto process. These can be utilized in different applications too. These Products have a lot of interest on the lookout.

These are widely renowned when it comes to rotational trim applications, due to their exceptional actual properties (astounding natural pressure break opposition and effect execution) and simplicity of handling.

Rototech Industries is a leading player based in Ahmedabad, a city known for its vibrant industrial landscape and growing business opportunities. Situated in Gujarat, a state renowned for its economic prosperity and industrial development, the company is strategically positioned to cater to a diverse range of markets. With its strong roots in Ahmedabad and India’s emerging market, Rototech Industries continues to drive innovation and provide top-quality solutions across industries both locally and globally.

Rototech Inquiry Form

Rototech

| Packaging Size | 20 Kgs |

| Packaging Type | Bags |

| Physical State | Powder |

| Brand | rototech |

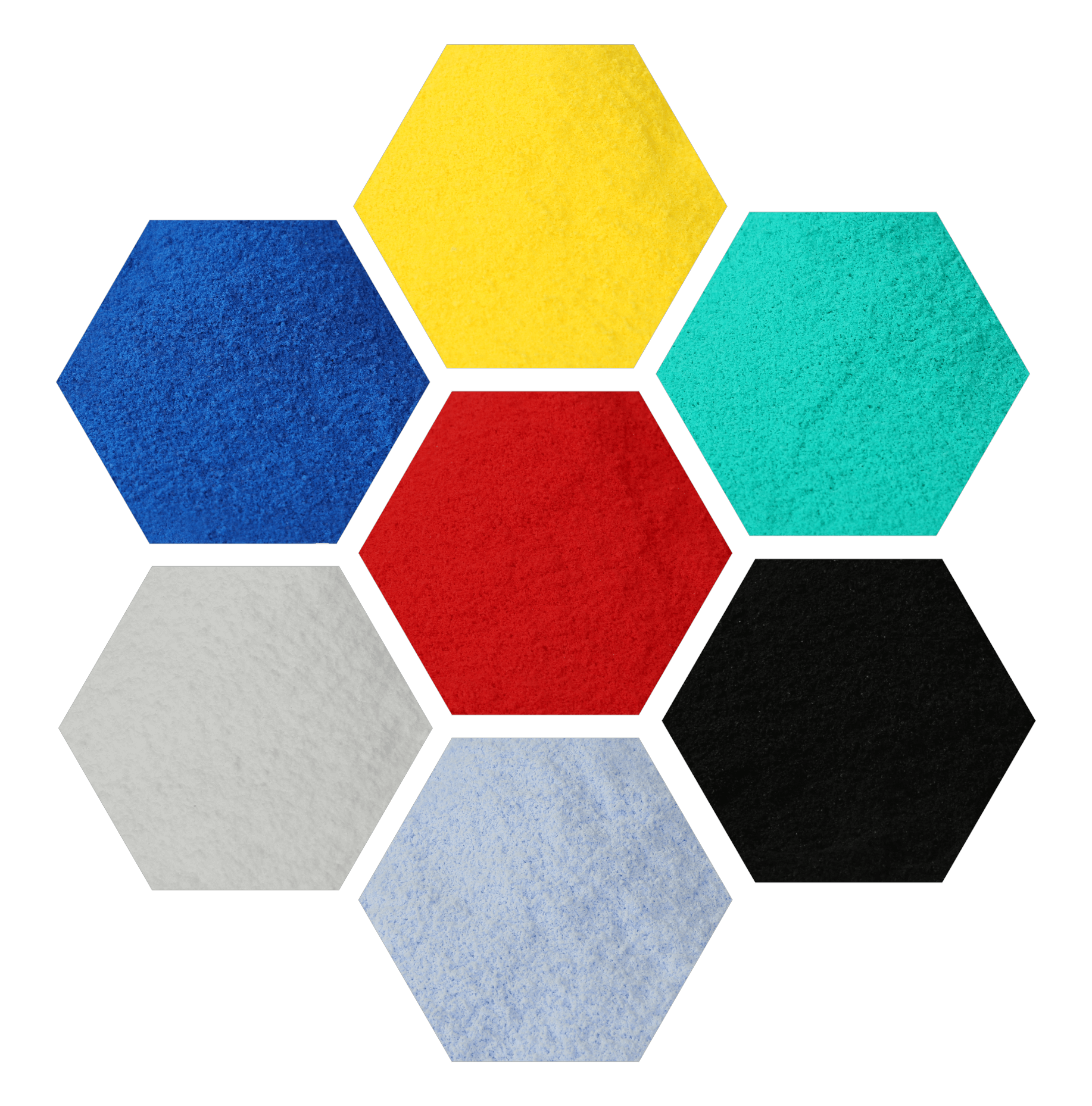

| Colour Availability | Red, Sea Green, Yellow, Blue, Blue Tone, Black, White, Grey, Custom |

| Applications | Traffic Cone, Underground Tank, Mobile Portable Toilet, Ice Box, Septic Tank |

| Grade Standard | Technical Grade |

| Usage | Industrial |

| Density | 0.936 gm/cm3 |

| Melt Flow Rate (MFR) | 4.5 gm/10 min |

| Tensile Strength Yield | (185) (18) (2610) (kg/cm2) (Mpa) (Psi) |

| Tensile Strength at Break | (120) (11.75) (1705) (kg/cm2) (Mpa) (Psi) |

| Storage | Bags should be stored in dry/closed conditions at temperature below 50 oC |

| Elongation at Break | 165% |

| Price | 100 Rupees to 180 Rupees Per Kilogram |

| Minimum Order Quantity | 500 Kilograms |

| Sample | Paid Sample Available |

| *Note: This is the Standard Technical Specification, It May Change based on End Product Applications & Custom Requirements | |

Properties of LLDPE Powder in Rotomoulding

Density and Molecular Structure:

These powders are characterized by its lower density compared to its other equivalent property of high-density. Due to its lower density it helps in improved flexibility and impact resistance. These materials are branched which helps molecular structure to enhance its toughness and tensile strength.

Melt Flow Index (MFI):

This Powder comes up with higher melt flow index compare to other polyethylene (PE) materials. Higher the MFI, Faster the melting & flow in rotomoulding process. Higher MFI also helps in reduced cycle times & increased production efficiency.

Flexibility and Impact Resistance:

These powders molecular structure made in such a way that helps in excellence flexibility and impact resistance to the final finished products. These products are ideal where the product is required extensive durability & ability to cope up with the external force that cause cracking or breaking.

Chemical Resistance:

It has great chemical resistance, acids and alkalis which help in products application that involves exposure to harsh environments or corrosive substances.

UV Stability:

These Powders can be incorporated with UV Stabilizers to enhance its resistance to ultraviolet radiation. These powders are is ideal for outdoor products where products are exposed to direct sunlight for longer period of times.

Applications of LLDPE Powder in Rotomoulding

Water Tanks and Containers:

80% to 90% of the LLDPE Powders are used to Manufacture Plastic Water Storage Tanks, Containers and plastic barrels. Due to its flexibility and chemical resistance properties it is ideal material for storing various liquids like water, chemical & industrial fluids.

Toys and Play Equipment:

Playground equipment being manufactured by such types of powders. Due to its impact resistance and durability, it is a best choice for producing toys, playground equipment, and recreational products. Our Powders helps products to withstand rough play and environmental conditions that requires products longevity and safety.

Automotive Components:

These powders are used to manufacture automotive components like fenders, interior trim parts and, fuel tanks these powders have great resistance to chemicals and impact strength makes it best choice for components exposed to oils, fuels, oils, and having various temperatures.

Agricultural Products:

These Powders has great chemical resistance which is suitable for storing fertilizers, pesticides and other agrochemicals. Applications involve agricultural tanks, containers, and bins.

Custom Containers and Pallets:

These powders also help in making custom size containers, pallets and storage solutions. Rotomoulding process is best when it comes to creative design flexibility, unique shapes and various sizes. These powders are best choice for such applications.

Advantages of Using LLDPE Powder in Rotomoulding

Cost-Effectiveness:

These powders have great cost effectiveness alongside with good balance properties these is ideal for the products where affordability is crucial and important.

Design Flexibility:

These powders are designer’s paradise as it comes up with some unique product having complex shapes, designs and contours.

Quick Cycle Times:

Quick Time Enables higher production at lower cost. The high MFI (Melt Flow Index) Helps faster melting and large production in quick succession.

Durability:

Products made from rotomoulding process and our powders have great product durability. Durability can be measured through product toughness and impact strength resistance. Products that have rough handling and environmental conditions our powders are the best choice for them.

Chemical Resistance:

Chemical Resistance is the crucial elements in end products. We use high & premium grade rotational grade materials to produce powders that enable to give good chemical resistance. It is best choice for the products that have direct involvement of various substances.

Conclusion:

LLDPE Powder is one of the essential elements in rotomoulding process. The quality of end finished rotomoulded products are largely depend upon the quality of the machine, manpower materials selecting the wrong material supply cause poor or inferior products.

You always need to consider certain technical, mechanical & end products before selecting the material supplier. You may also choose material supplier based on your high quality products, durable & cost effectiveness

These Powders have large range of product applications from plastic water storage tank to playground equipment.

As a reputed supplier in the market we would suggest you to consider properties like flexibility, impact resistance, chemical resistance, and UV stability, MFI (Melt Flow Index)

We, Rototech Industries are your one stop solution for your desired needs.

Following The Standard Procedure

During the production of Polyethylene (PE) an assortment of impetus and co-monomers can be utilized which additionally affect the properties of the PE. Butene (C4) comonomer is the most well-known giving minimal expense, great mechanical properties and the most broadly utilized.

R36I45 and R39I38 are both butene co-monomer based direct low thickness polyethylene (LLDPE) grade additives with cell reinforcements and UV stabilizers. Things delivered by these grades have a generally excellent harmony between mechanical properties and ESCR opposition. It has great hardness and shows great processability.

Entirely Safe And Reliable

This Powder meets the necessity specified in the standard on Specification for Polyethylene for safe use in touch with a food item, certain medical products and containers to store and package water.

Customized In Accordance With Your Requirement

Distinctive rotomoulding applications can require various grades of material for explicit execution prerequisites. We produce modified grades by intensifying various materials, adding substances and by changing the granulating determinations as required.

Reliable And Easily Transportable Packing

The pack configuration is redone to guarantee strategic comfort while taking care of. The packs are set apart with powder clump subtleties on 2 sides which guarantees regardless of how it is stacked, it is simple for administrators to distinguish the material. Packs ought to be put away in dry/shut conditions at a temperature under 50 ℃. At the point when filled it comes to fruition of box that guarantees simple dealing with while stacking and dumping on stacks/beds. Being pressed on automated pressing lines guarantees definite weight, spillage verification alongside incredible dampness obstruction.

Why Choose Us

Rototech Industries is counted amongst the leading manufacturer of LLDPE Rotomoulding Powder in Gujarat.

- Trust

- Transparency

- Ethical Business Policy

- After Sales Service

- New Product Development Help

Grades Detail

Grading of Rotoethene Powders is based on

- Density

- Melt flow

- Impact resistance

- Rigidity

- ESCR (environmental stress crack resistance

- Grind type

- Custom compound colors

ROTOETHENE Grades Specifications | Grade Name | |||||

RototechR36I45 | RototechR39I38 | |||||

Specimen Type | ||||||

Parameter | Standard | UOM | Compression Molded | Rotomolded | Compression Molded | Rotomolded |

MFI | ASTM D1238 | gm/10 min | 4.5 | 3.8 | ||

Density | ASTM D 1505 | gm/cm3 | 0.936 | 0.939 | ||

Recommended PIAT * | In-lab StdPrc * | oC | 190 oC | 190 oC | ||

Tensile Strength at Yield | ASTM D638 | (kg/cm2) (Mpa) (Psi) | (180) (17.5) (2540) | (185) (18) (2610) | (215) (21) (3050) | (210) (20.5) (2975) |

Tensile Strength at Break | ASTM D638 | (kg/cm2) (Mpa) (Psi) | – | (120) (11.75) (1705) | – | (120) (11.75) (1705) |

IZOD Impact Strength | ASTM D256 | Kg.cm/cm | 25 | 22 | ||

ARM Low Temperature | ARM Standard (3.17mm @ -40 oC/oF) | (J/mm) (ft/lbs) | – | (22) (80) | – | (22) (80) |

Flexural Modulus At 1% Strain | ASTM D790 | (kg/cm2) (Mpa) (Psi) | (6000) (590) (85575) | (2300) (225) (32630) | (9000) (880) (127625) | (2300) (225) (32630) |

Elongation at Yield | ASTM D638 | % | 20 | 14 | 15 | 12 |

Elongation at Break | ASTM D638 | % | 600 | 165 | 350 | 110 |

ESCR | ASTM D1693 | Hrs | 350 | 350 | 300 | 300 |

*PIAT For moulding oven temperature was 300 oC and cube mould of size 175mmx175mmx175mm was moulded with wall thickness of 3.17mm.

Available Colours

Note: We can also make the custom powder based on your requirements.

FAQs

What does LLDPE stand for, and why is it used in rotomoulding?

LLDPE (Linear Low-Density Polyethylene) is a thermoplastic polymer used in rotomoulding due to its high flexibility, impact resistance, and excellent durability.

Linear molecular structure: Provides improved toughness compared to conventional LDPE (Low-Density Polyethylene).

High elongation properties: Ensures flexibility in moulded parts.

Superior stress crack resistance: Ideal for tanks, containers, and industrial products.

What are the main raw materials used in manufacturing LLDPE rotomoulding powder?

Ethylene (C₂H₄) – The primary building block.

Alpha-olefins (e.g., butene, hexene, octene) – Improve polymer flexibility and strength.

Catalysts (Ziegler-Natta or Metallocene Catalysts) – Control polymerization for better material properties.

What is the particle size distribution of LLDPE rotomoulding powder, and why is it important?

Standard size: 200-500 microns (µm).

Importance:

Smaller particles (<300 µm) → Faster melting, smoother finish.

Larger particles (>400 µm) → Uneven melting, rough texture.

Consistent size ensures uniform wall thickness in moulded products.

What is the specific gravity of LLDPE, and how does it affect product weight?

Specific Gravity (SG): 0.915 – 0.940 g/cm³ (ASTM D792).

Impact on weight:

Lower SG → Lighter products, ideal for transport applications.

Higher SG → Denser, stronger products, used for structural applications.

What is the typical Melt Flow Index (MFI) of LLDPE rotomoulding powder?

Melt Flow Index (MFI) measures polymer flow rate at 190°C under a 2.16 kg load (ASTM D1238).

Standard range: 3-7 g/10 min.

Higher MFI → Faster flow, thinner walls.

Lower MFI → Higher viscosity, stronger walls.

What is the Vicat Softening Temperature (VST) of LLDPE?

Vicat Softening Temperature (VST) determines when the polymer begins to soften under heat (ASTM D1525).

Range: 85-110°C.

Higher VST → Better high-temperature performance.

What is the Heat Deflection Temperature (HDT) of LLDPE, and why is it important?

HDT (ASTM D648): Measures deformation under load at 0.46 MPa pressure.

LLDPE HDT: 40-60°C.

Importance:

Ensures shape retention under heat.

Prevents warping in outdoor applications.

How does LLDPE resist impact forces, and what is its Izod Impact Strength?

Izod Impact Strength (ASTM D256): 50-150 J/m.

Higher values indicate better resistance to cracks and mechanical shocks.

Ideal for water tanks, automotive parts, and industrial containers.

What is the Tensile Strength of LLDPE, and why is it important?

Tensile Strength (ASTM D638): 10-25 MPa (Megapascals).

Importance:

Determines ability to withstand stretching forces.

Stronger LLDPE → More durable, long-lasting products.

What is the Environmental Stress Crack Resistance (ESCR) of LLDPE?

ESCR (ASTM D1693): Measures polymer resistance to cracking under chemical exposure.

LLDPE ESCR is high, making it suitable for chemical storage tanks and industrial applications.

How does LLDPE perform in UV exposure, and what are UV stabilizers?

UV resistance (ASTM G154): LLDPE requires UV stabilizers to prevent degradation.

UV stabilizers: Hindered Amine Light Stabilizers (HALS) and Carbon Black.

Without UV stabilizers: Cracking, brittleness, and color fading occur over time.

What is the Coefficient of Linear Thermal Expansion (CLTE) of LLDPE?

CLTE (ASTM D696): 150-200 x 10⁻⁶ mm/m°C.

Impact:

Higher CLTE → More expansion in heat, risk of warping.

Lower CLTE → More dimensional stability.

What is the abrasion resistance of LLDPE, and how is it tested?

Abrasion Resistance (ASTM D1044):

Measured using Taber Abrasion Test (rotating disk wear test).

LLDPE has excellent wear resistance, ideal for road safety barriers, chemical drums, and marine buoys.

How does LLDPE behave under hydrostatic pressure?

Hydrostatic Pressure Test (ASTM D2837):

LLDPE can withstand up to 10 bar of pressure.

Used in underground storage tanks and high-pressure pipes.

What is the shrinkage rate of LLDPE after molding?

Shrinkage: 1.5 – 3.0%.

Influenced by:

- Cooling rate.

- Processing temperature.

Higher shrinkage → Dimensional inaccuracy, warping issues.

How does LLDPE interact with chemicals?

Resistant to:

Acids, bases, alcohols, and salts.

Not resistant to:

Strong oxidizers (e.g., Nitric Acid).

Chemical Resistance Test (ASTM D543).

What is the Water Absorption Rate of LLDPE?

Water Absorption (ASTM D570): <0.01% (Negligible).

Significance:

Perfect for marine applications, water tanks, and floatation devices.

What is the Surface Resistivity of LLDPE in electrical applications?

Surface Resistivity (ASTM D257): 10¹⁵ ohm.cm.

High resistivity → Excellent electrical insulation.

How does LLDPE compare with HDPE in rotomoulding?

| Property | LLDPE | HDPE |

| Flexibility | High | Moderate |

| Impact Strength | Excellent | Good |

| Chemical Resistance | Very Good | Excellent |

| UV Stability | Can be enhanced | Better |

| Melt Flow Index | 3-7 g/10 min | 0.2-2 g/10 min |

How does LLDPE contribute to sustainability and recycling?

Resin identification code: #4 (LDPE family).

100% recyclable up to 5 times.

Used in eco-friendly applications like recycled storage tanks, sustainable packaging, and green construction materials.