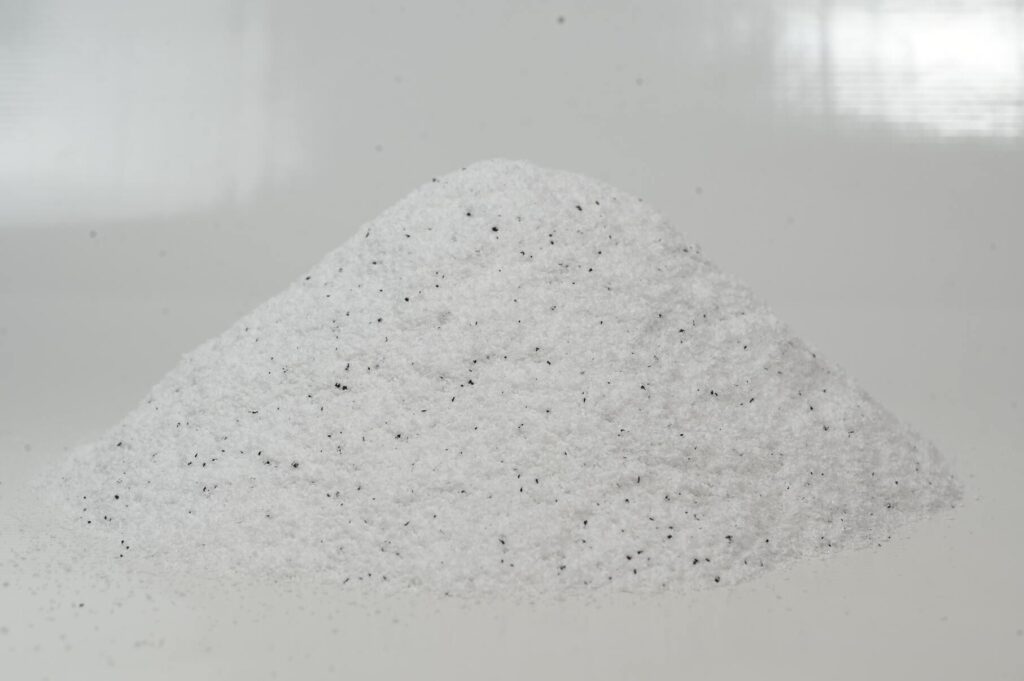

Marble Stone Granite Sand Effects Rotomoulding Powder

Rototech Industries is one of the leading manufacturers, suppliers, and exporters of Marble Stone Granite Sand Effects Rotomoulding Powder. Our factory is set up in Ahmedabad, Gujarat, India

In the last few years, we have launched various innovative products. As a result, our powders are suitable for multiple industries and use.

We at Rototech Industries offer high-quality materials and have been experts in the rotational molding application process.

At Rototech Industries, we offer aesthetically appealing products and various grades of a powder suitable for multiple industrial applications, including the furniture industry.

Marble Rotomoulding Powder

Technical Specifications

| Packaging Size | 20 Kgs |

| Packaging Type | Bags |

| Physical State | Powder |

| Brand | rototech |

| Colour Availability | Black Granite, Black Stone, Blue Granite, Red Granite, Sand Marble, Sand Stone, White Stone, Yellow Granite |

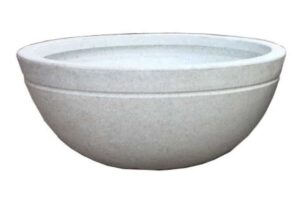

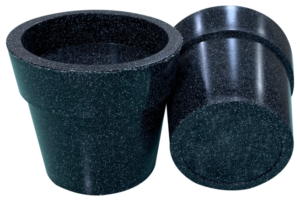

| Applications | Granite Flower Pot, Planter, Terracotta Planter, White Planter, Water Storage Tanks, Square Wheels, Bowl Type Pot |

| Grade Standard | Technical Grade |

| Usage | Commercial, Agricultural, Residential, Industrial |

| Storage | Bags should be stored in dry/closed conditions at temperature below 50 oC |

| Price | 100 Rupees to 180 Rupees Per Kilogram |

| Minimum Order Quantity | 500 KGs |

| Sample | Paid |

| *Note: This is the Standard Technical Specification, It May Change based on End Product Applications & Custom Requirements | |

Any product’s value is significantly increased with alluring and charming aesthetics. One of the best processes where aesthetically engaging design combines with technology is in Rotation Moulding Application, known as Rotomoulding or famously as Designers Paradise.

With us, you can get roto grade powders for different designs and effects. The functioning of the powders with the technology offers fascinating color effects with a unique flow of form that creates a visually exquisite product.

At Rototech Industries, in the process of offering the best rotomolding products that are attractive to look at, we have developed special effects powders.

The designers and architects use our powders immensely. Therefore, we offer refined roto-molding objects that can be customized for various applications.

The products are especially effective for use on any surface structure, and we offer our clients the option of custom coloring the products.

Using marble for construction has been an age-old tradition. However, despite the emergence of ceramic tiles and those being less costly than stone when it comes to the flooring of a building, people opt for the later options instead. The simple reason is that they offer a natural and earthy yet sophisticated and classic look to the place.

For the rotational molding process, we are offering the same, i.e. marble stone granite sand effects rotomoulding powder.

Over the years, we have invested heavily in conducting extensive research and developing these effects, creating a comprehensive range of powder, which can be efficiently used in the roto-molding process.

Moreover, we understand that every person has different aesthetics and preferences for the powder effects & colors. Therefore, as part of our service, we offer the customers the choice to customize their colors and products, which we develop and produce for them.

Feel free to contact us and get a free sample for your requirement. Also, you can request a quote.

Available Colors

Applications

FAQs

What is Marble Stone Granite Sand Effects Rotomoulding Powder?

This is a specially formulated polyethylene (PE) rotational molding powder designed to create marble, stone, granite, or sand-like effects in molded products. It contains a blend of natural-looking pigments, metallic or mineral-based fillers, and special additives to mimic the appearance of real stone while maintaining the lightweight and durability of plastic.

How is the stone-like texture achieved in rotomoulding?

The texture and visual effect are created using:

Multi-tone color blending – Different colored resin granules or pigments are combined.

Granular additives – Small solid particles mimic the rough texture of natural materials.

Controlled heating and rotation – Helps distribute colors and textures evenly.

What types of effects can be achieved with this powder?

Marble Effect – Swirling blend of two or more colors.

Granite Effect – Speckled appearance like natural granite.

Sandstone Effect – Soft, grainy textures.

Stone Effect – Rough surface texture similar to real stone.

What is the composition of Marble Stone Granite Sand Effects Rotomoulding Powder?

LLDPE (Linear Low-Density Polyethylene) – Base polymer for flexibility.

Mineral-Based Fillers – Such as mica, silica (SiO₂), or calcium carbonate (CaCO₃) for texture.

Pigments & Colorants – Natural stone-like colors.

UV Stabilizers (HALS – Hindered Amine Light Stabilizers) – Protect against sun exposure.

What is the Melt Flow Index (MFI) of this powder?

MFI (ASTM D1238): 3-7 g/10 min at 190°C, 2.16 kg load.

Lower MFI provides better strength but requires higher processing temperatures.

What is the density of Marble Effect Rotomoulding Powder?

Density (ASTM D792): 0.925 – 0.945 g/cm³.

The addition of mineral fillers can slightly increase the density.

Does this powder contain UV stabilizers?

Yes, it includes UV stabilizers like HALS (Hindered Amine Light Stabilizers) to prevent fading and material degradation when exposed to sunlight.

Can Marble Effect Rotomoulding Powder be used for outdoor applications?

Yes, it is UV-resistant and weatherproof, making it suitable for:

Garden planters & pots

Architectural elements

Outdoor furniture

Decorative sculptures

Is this powder suitable for food-grade applications?

Food-grade versions are available, but not all stone-effect powders are FDA (Food and Drug Administration) or NSF (National Sanitation Foundation) certified.

Non-toxic pigments must be used for applications like water tanks or food containers.

What is the impact strength of this powder?

Izod Impact Strength (ASTM D256): 50-120 J/m.

The presence of mineral fillers may slightly reduce impact resistance, but it remains suitable for medium-duty applications.

How is the surface finish of the final molded product?

The final surface depends on:

Mold surface texture – Smooth molds create polished finishes, rough molds create matte effects.

Processing temperature – Higher temperatures may enhance blending but affect texture clarity.

Additive distribution – Ensuring even dispersion of pigments and fillers is crucial.

What is the thermal stability of this rotomoulding powder?

Heat Deflection Temperature (HDT, ASTM D648): 40-65°C at 0.46 MPa.

Service Temperature Range: -40°C to +80°C.

Thermal Conductivity: Lower than metal or stone, making it a good insulator.

What are the advantages of using this powder over real stone?

Lightweight – Much easier to handle than natural stone.

Weather-resistant – Does not crack like real stone in extreme temperatures.

Cost-effective – Cheaper than natural stone alternatives.

Moldability – Can be formed into any shape or size.

How does the addition of mineral fillers affect the mechanical properties?

Slightly increases density for a more stone-like feel.

Reduces shrinkage during molding, improving dimensional accuracy.

May lower flexibility slightly compared to standard LLDPE powders.

What are the recommended processing conditions for this powder?

| Parameter | Recommended Range |

| Oven Temperature | 200-250°C |

| Dwell Time | Varies based on part size |

| Cooling Rate | Gradual air cooling preferred |

Can this powder be customized for specific colors or effects?

Yes, manufacturers can blend different pigments to create:

Custom marble patterns (e.g., white with black veins).

Granite-like speckles (e.g., gray with black and red flecks).

Sandy or earthy tones (e.g., beige, brown, terracotta).

What are the best mold types for this powder?

Aluminum molds – Best for detailed textures.

Steel molds – Provide durability for high-volume production.

Silicone-lined molds – Useful for achieving fine patterns.

How does this powder compare to standard rotomoulding powder?

| Feature | Marble/Stone Effect Powder | Standard Rotomoulding Powder |

| Aesthetic Appeal | High (Realistic stone look) | Plain solid colors |

| Texture | Can be rough or smooth | Usually smooth |

| UV Resistance | High | Standard |

| Weight | Slightly heavier | Lighter |

| Cost | Higher due to pigments & fillers | Lower |

Can anti-slip properties be added to this material?

Yes, adding textured finishes or anti-slip agents like silica-based particles can improve grip, making it ideal for flooring or stepping surfaces.

What are some common applications for this type of rotomoulding powder?

Architectural panels & facades – Stone-like designs for construction.

Garden décor & planters – Imitates natural stone with reduced weight.

Outdoor furniture – Tables, benches, and chairs.

Marine applications – Decorative, UV-resistant components.

Statues & sculptures – Realistic look with plastic durability.