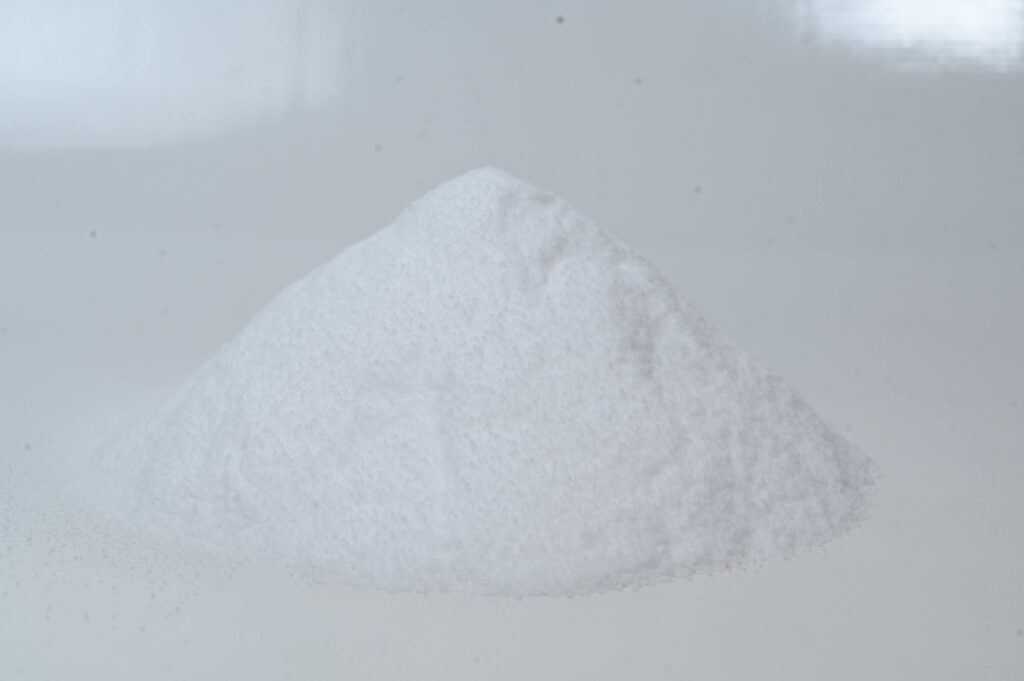

UV Rotomoulding Powder

Our UV Rotomoulding Powder is developed to ensure the colors don’t fade under direct sunlight of the material. The term ‘long haul outside execution’ is standard for roto-molders, mainly when it comes to offering UV settles crude materials. But in most cases, the decays under the direct sunlight for the polymer are quite common.

Furthermore, the UV-resistant materials for roto-molding balance the ESCR resistance and mechanical properties to ensure that the clients are not disappointed with the material.

UV Rotomoulding Inquiry

Technical Specifications

| Packaging Size | 20 Kgs |

| Packaging Type | Bags |

| Physical State | Powder |

| Brand | rototech |

| Colour Availability | Blue, Milky white, Blue Tone, White, Black, Golden Yellow, Red, Green, Orange, Brown, Yellow, Off White, Grey, Cyan |

| Applications | Barrel, Biogas Tanks, Chemical Storage Tanks, Drum, Oil Fuel Tanks, Plastic Dustbins, Plastic Pallets, Road Barrier, Traffic Cone, Water Tanks, Trolley, Tool Box, Collapsible Box, Containers, Utility Wheel Barrow |

| Grade Standard | Technical Grade |

| Usage | Commercial, Agricultural, Industrial |

| Density | 0.938 gm/cm3 (ASTM D 1505) |

| Melt Flow Rate (MFR) | 4 gm/10 min (ASTM D 1238 @ 190 C, 2.16 kg) |

| Tensile Strength Yield | 20 (Mpa) 2900 psi / ASTM D 638 @ Speed 50 mm / min |

| Tensile Strength at Break | 18 (Mpa) 2600 psi / ASTM D 638 @ Speed 50 mm / min |

| Melting Point | 125 (C)/ 257 F (ASTM D 2117) |

| Storage | Bags should be stored in dry/closed conditions at temperature below 50 oC |

| Price | 100 Rupees to 180 Rupees Per Kilogram |

| Minimum Order Quantity | 500 KGs |

| Sample | Paid |

| *Note: This is the Standard Technical Specification, It May Change based on End Product Applications & Custom Requirements | |

Why Use

Extensive research has been made to develop the Ultraviolet Roto Moulding Powder to ensure that the synthetic material can withstand extreme heat and sunlight. Hence our experts have manufactured and sourced the best quality materials which are procured from international standard.

We source the material from authorized and legally approved market vendors and make the powder undergo random checks before dispatching it to our clients to ensure they are of the highest quality.

A UV roto grade powder will ensure that the product lasts longer under the sun and does not disintegrate quickly.

The powder is available to our clients in blue, milky white, blue tone, white, black, golden yellow, orange, and other customized colours requested by the clients.

Available Colours

Applications

FAQs

What is UV Rotomoulding Powder?

UV Rotomoulding Powder is a polyethylene-based (PE) rotational molding powder that contains UV stabilizers to enhance resistance against ultraviolet (UV) radiation from sunlight. It prevents material degradation, discoloration, and brittleness due to prolonged sun exposure.

What does UV resistance mean in rotomoulding powder?

UV resistance refers to the ability of a material to withstand damage from ultraviolet (UV) rays. Prolonged exposure to sunlight can break down polymers, leading to:

Loss of mechanical strength (brittleness and cracking).

Color fading and chalking (surface degradation).

Reduced lifespan of products exposed to outdoor conditions.

What are the key components of UV Rotomoulding Powder?

LLDPE (Linear Low-Density Polyethylene) – Provides flexibility and toughness.

UV Stabilizers (Hindered Amine Light Stabilizers – HALS) – Absorb and neutralize UV rays.

Antioxidants (AO) – Prevent degradation due to heat and oxygen.

Pigments & Additives – Enhance color and performance.

What is HALS (Hindered Amine Light Stabilizers), and how does it work?

HALS (Hindered Amine Light Stabilizers) are chemical additives that:

Trap free radicals formed by UV exposure.

Prevent oxidation and degradation of the polymer chains.

Extend the life of plastic products used in outdoor applications.

How is UV stability measured in Rotomoulding Powder?

UV stability is tested using:

- ASTM G154 (Fluorescent UV Exposure Test) – Simulates outdoor weathering conditions.

- ASTM D2565 (Outdoor UV Weathering Test) – Measures material performance under real-world sunlight exposure.

Results are measured in:

- Hours of UV exposure before degradation.

Retention of mechanical properties after UV aging tests.

What is the UV Rating of Rotomoulding Powder?

UV rotomoulding powder is rated from UV 2 to UV 20, where:

UV 2: Suitable for indoor or minimal sunlight exposure.

UV 8-12: Ideal for outdoor applications with moderate sun exposure.

UV 15-20: Designed for extreme outdoor conditions (desert, high-altitude regions).

How does UV Rotomoulding Powder compare to standard (non-UV) powder?

Property | UV Rotomoulding Powder | Standard Rotomoulding Powder |

UV Resistance | High | Low |

Color Retention | Long-lasting | Fades quickly |

Lifespan in Sunlight | 5-10 years | 1-3 years |

Cost | Slightly higher | Lower |

What types of UV stabilizers are used in Rotomoulding Powder?

The two main types of UV stabilizers are:

UV Absorbers – Convert UV rays into heat (e.g., Benzophenones, Benzotriazoles).

Hindered Amine Light Stabilizers (HALS) – Prevent polymer breakdown over time.

What is the effect of UV exposure on polyethylene?

Without UV protection, polyethylene undergoes:

Oxidative degradation – Loss of molecular integrity.

Surface chalking – Powdery white layer formation.

Loss of mechanical strength – Becomes brittle and cracks.

What is the density of UV Rotomoulding Powder?

Density (ASTM D792): 0.915 – 0.940 g/cm³.

LLDPE-based UV powder has a lower density for better flexibility.

What is the Melt Flow Index (MFI) of UV Rotomoulding Powder?

MFI (ASTM D1238): 3-7 g/10 min at 190°C, 2.16 kg load.

Higher MFI means easier flow during molding, but may reduce impact strength.

What is the Heat Deflection Temperature (HDT) of UV Rotomoulding Powder?

HDT (ASTM D648): 40-60°C at 0.46 MPa.

UV stabilizers slightly improve heat resistance but do not make it heatproof.

What is the impact strength of UV Rotomoulding Powder?

Izod Impact Strength (ASTM D256): 50-150 J/m.

UV stabilization does not affect impact strength significantly.

Can UV Rotomoulding Powder be used for potable (drinking) water tanks?

Yes, if it meets FDA (Food and Drug Administration) and NSF (National Sanitation Foundation) standards. UV additives must be food-safe and non-toxic.

How does UV Rotomoulding Powder resist chemical exposure?

Chemical Resistance (ASTM D543): Excellent resistance to acids, bases, and oils.

UV stabilizers do not affect chemical resistance.

What is the Coefficient of Linear Thermal Expansion (CLTE)?

CLTE (ASTM D696): 140-200 x 10⁻⁶ mm/m°C.

Higher UV exposure slightly increases CLTE, leading to more expansion/contraction in extreme temperatures.

What is the expected lifespan of UV Rotomoulding Powder products?

UV 8-12 Powder: 5-8 years in direct sunlight.

UV 15-20 Powder: 10-15 years in extreme UV conditions.

What are the common applications of UV Rotomoulding Powder?

Outdoor water tanks – Prevents UV-induced degradation.

Road barriers & traffic cones – Maintains color stability.

Agricultural equipment – UV-stable for farming containers.

Marine buoys & floats – Resists UV and water exposure.

How does UV Rotomoulding Powder affect surface finish and aesthetics?

Maintains gloss and smoothness over time.

Prevents fading and chalking in colored products.

Is UV Rotomoulding Powder flame retardant?

Standard UV powder is NOT flame retardant.

Flame Retardant (FR) additives, such as Aluminum Trihydrate (ATH), can be added if fire resistance is required.