Virgin Rotomoulding Powder

Rototech Industries is one of the leading manufacturer, supplier & exporter of Virgin Rotomoulding Powder.

The break obstruction ought to be a significant thought while choosing a grade of polyethylene for a specific application. When exposed to worry about a timeframe most materials normally fizzle by breaking. Comprehend that various grades of Polyethylene can display limitlessly unique execution regarding break obstruction.

The break opposition of a particular grade of Linear Low-Density Polyethylene is represented generally by the size of its atoms (demonstrated by its Melt Index) and the sort and level of comonomer utilized in its production. Comonomers like butene (C4), hexene (C6) and octene (C8) are responded into the polymer affix to deliver little side chains which thus make a deviation, or change of point in the atom chain.

Virgin Rotomoulding Powder

Virgin Inquiry

| Packaging Size | 20 Kgs |

| Packaging Type | Bags |

| Physical State | Powder |

| Brand | rototech |

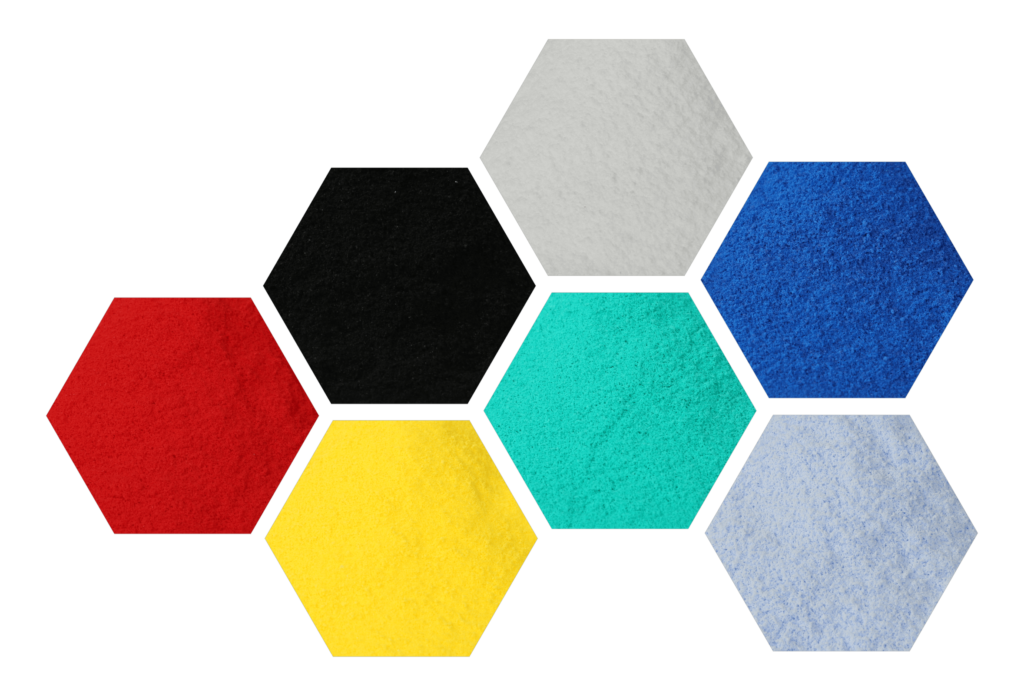

| Colour Availability | Red, Sea Green, Yellow, Blue, Blue Tone, Black, White, Grey, Custom |

| Applications | Kayak, Refrigeration System, Fish Box, Tractor Hood, Ice Box, Fuel Tank, Insulated Box, Tractor Interior, Marine Buyos, Exhibition Tool Box, Playground Equipments, Truck Mudguard |

| Grade Standard | Technical Grade |

| Usage | Industrial |

| Density | 0.939 gm/cm3 |

| Melt Flow Rate (MFR) | 4 gm/10 min |

| Tensile Strength Yield | (200) (19.75) (2865) (kg/cm2) (Mpa) (Psi) |

| Tensile Strength at Break | (125) (12.25) (1775) (kg/cm2) (Mpa) (Psi) |

| Storage | Bags should be stored in dry/closed conditions at temperature below 50 oC |

| Elongation at Break | 250% |

| Price | 100 Rupees to 180 Rupees Per Kilogram |

| Minimum Order Quantity | 500 Kilograms |

| Sample | Paid Sample Available |

| *Note: This is the Standard Technical Specification, It May Change based on End Product Applications & Custom Requirements | |

Reliable Performance And Expected Outcomes

The impact of this difference in point is fairly similar to the impact of a bunch in a piece of wood. Polyethylene turns out to be harder to part. The size and amount of comonomer atoms acquainted with the polymer affix decide how much the break obstruction is improved. For instance, the side chain made by the fuse of hexene is double the size of that made by the consolidation of butene. Therefore, the chain deviation brought about by hexene is fundamentally more noteworthy than that brought about by the fuse of butene and results in the hexene VIRGIN (PRIME) ROTOMOULDING POWDER displaying a break opposition roughly multiple times better compared to the butene VIRGIN (PRIME) ROTOMOULDING POWDER. The fuse of octene into the polymer chain makes just a somewhat bigger deviation than that made by the joining of hexene and the adjustment of break obstruction is less critical.

Customized For Your Requirement

Diverse rotomoulding applications can require various grades of material for explicit execution prerequisites. We produce tweak grades by intensifying various materials, adding substances and by changing the pounding determinations as required.

Packed And Ready To Go On-Demand

The pack configuration is redone to guarantee strategic accommodation while taking care of. At the point when filled it comes to fruition of box that guarantees simple taking care of while stacking and dumping on stacks/beds. Being pressed on automated pressing lines guarantees precise weight, spillage evidence alongside fantastic dampness obstruction. The sacks are set apart with powder clump subtleties on 2 sides which guarantees regardless of how it is stacked, it is simple for administrators to distinguish the material. Sacks ought to be put away in dry/shut conditions at a temperature under 50 ℃.

Grades Detail

Grading of Rotoethene Powders is based on

- Density

- Melt flow

- Impact resistance

- Rigidity

- ESCR (environmental stress crack resistance

- Grind type

- Custom compound colors

ROTOETHENE Grades Specifications | Grade Name | |||

R39I04 | ||||

Specimen Type | ||||

Parameter | Standard | UOM | Compression Molded | Rotomolded |

MFI | ASTM D1238 | gm/10 min | 4 | |

Density | ASTM D 1505 | gm/cm3 | 0.939 | |

Recommended PIAT * | In-lab Std Prc * | oC | 200 oC | |

Tensile Strength at Yield | ASTM D638 | (kg/cm2) (Mpa) (Psi) | (205) (20) (2900) | (200) (19.75) (2865) |

Tensile Strength at Break | ASTM D638 | (kg/cm2) (Mpa) (Psi) | – | (125) (12.25) (1775) |

IZOD Impact Strength | ASTM D256 | Kg.cm/cm | 50(Partial Break) | |

ARM Low Temperature | ARM Standard (3.17mm @ -40 oC/oF) | (J/mm) (ft/lbs) | – | (28) (115) |

Flexural Modulus At 1% Strain | ASTM D790 | (kg/cm2) (Mpa) (Psi) | (7650) (750) (108775) | (2550) (250) (36260) |

Elongation at Yield | ASTM D638 | % | 20 | 13 |

Elongation at Break | ASTM D638 | % | 950 | 250 |

ESCR | ASTM D1693 | Hrs | 500 | 500 |

*PIAT For moulding oven temperature was 300 oC and cube mould of size 175mmx175mmx175mm was moulded with wall thickness of 3.17mm.

Available Colours

Note: We can also make the custom powder based on your requirements.

FAQs

What is Virgin Rotomoulding Powder, and how does it differ from Recycled Powder?

Virgin Rotomoulding Powder is made from pure, unprocessed polymer resins without any recycled content. It provides:

- Higher molecular integrity → Better mechanical strength.

- Better consistency in color and finish → Ideal for premium rotomoulded products.

- Superior durability and impact resistance compared to recycled materials.

What is the base polymer used in Virgin Rotomoulding Powder?

The most commonly used polymer is LLDPE (Linear Low-Density Polyethylene).

It may also contain HDPE (High-Density Polyethylene) or other specialized resins for specific applications.

What is the particle size distribution of Virgin Rotomoulding Powder?

Typical range: 200-500 microns (µm).

Importance:

Ensures uniform melting and even wall thickness.

Prevents air entrapment during molding, leading to a smooth surface finish.

What is the Specific Gravity (SG) of Virgin Rotomoulding Powder?

Range: 0.915 – 0.940 g/cm³ (ASTM D792).

Impact:

Lower SG → Lightweight, ideal for portable tanks and containers.

Higher SG → Denser material, suitable for heavy-duty applications.

What is the Melt Flow Index (MFI) of Virgin Rotomoulding Powder?

MFI (ASTM D1238): 3-7 g/10 min at 190°C, 2.16 kg load.

Significance:

Higher MFI → Faster flow, thinner walls.

Lower MFI → Higher viscosity, thicker and stronger walls.

What is the Vicat Softening Temperature (VST) of Virgin Rotomoulding Powder?

VST (ASTM D1525): 85-110°C.

Importance:

Determines the heat resistance of molded products.

Higher VST prevents warping under high temperatures.

What is the Heat Deflection Temperature (HDT) of Virgin Rotomoulding Powder?

HDT (ASTM D648): 40-60°C at 0.46 MPa pressure.

Importance:

Ensures stability under moderate heat loads.

Prevents deformation in outdoor storage tanks and industrial containers.

What is the Izod Impact Strength of Virgin Rotomoulding Powder?

Izod Impact Strength (ASTM D256): 50-150 J/m.

Higher impact strength ensures resistance to cracking and mechanical shocks.

What is the Tensile Strength of Virgin Rotomoulding Powder?

Tensile Strength (ASTM D638): 10-25 MPa.

Significance:

Determines the maximum stretching force the material can withstand.

Higher tensile strength results in stronger, more durable products.

What is the Environmental Stress Crack Resistance (ESCR) of Virgin Rotomoulding Powder?

ESCR (ASTM D1693): Measures resistance to cracking under chemical and mechanical stress.

High ESCR makes it ideal for chemical tanks and industrial storage applications.

How does Virgin Rotomoulding Powder perform under UV exposure?

UV stability (ASTM G154): Requires UV stabilizers to prevent degradation.

UV stabilizers include:

HALS (Hindered Amine Light Stabilizers) → Prevents polymer breakdown.

Carbon Black → Enhances UV resistance.

What is the Coefficient of Linear Thermal Expansion (CLTE) of Virgin Rotomoulding Powder?

CLTE (ASTM D696): 150-200 x 10⁻⁶ mm/m°C.

Impact:

Lower CLTE → Better dimensional stability in varying temperatures.

How does Virgin Rotomoulding Powder resist abrasion and surface wear?

Abrasion Resistance (ASTM D1044):

High resistance to scratching and wear.

Used in road safety barriers, marine buoys, and industrial drums.

How does Virgin Rotomoulding Powder perform under hydrostatic pressure?

Hydrostatic Pressure Test (ASTM D2837):

Can withstand up to 10 bar pressure.

Suitable for underground tanks and high-pressure applications.

What is the shrinkage rate of Virgin Rotomoulding Powder after molding?

Shrinkage: 1.5 – 3.0%.

Factors affecting shrinkage:

Cooling rate – Faster cooling can increase shrinkage.

Processing temperature – Overheating can cause excess shrinkage.

How resistant is Virgin Rotomoulding Powder to chemicals?

Chemical Resistance (ASTM D543):

Highly resistant to acids, bases, and organic solvents.

Not resistant to strong oxidizers like concentrated sulfuric acid (H₂SO₄).

What is the Water Absorption Rate of Virgin Rotomoulding Powder?

Water Absorption (ASTM D570): <0.01% (Negligible).

Benefits:

Excellent for marine applications, water tanks, and flotation devices.

What is the Surface Resistivity of Virgin Rotomoulding Powder?

Surface Resistivity (ASTM D257): 10¹⁵ ohm.cm.

Significance:

Provides excellent electrical insulation.

Suitable for electrical enclosures and insulating components.

How does Virgin Rotomoulding Powder compare to Recycled Rotomoulding Powder?

| Property | Virgin Powder | Recycled Powder |

| Molecular Integrity | 100% pure resin | May contain impurities |

| Strength | Higher | Lower |

| Surface Finish | Smoother | May have defects |

| UV Stability | Better | May require additional stabilizers |

| Chemical Resistance | High | Moderate |

Is Virgin Rotomoulding Powder recyclable, and how sustainable is it?

Yes, it is recyclable.

Resin Identification Code: #4 (LDPE family).

Sustainability benefits:

Can be reused multiple times without losing mechanical properties.

Lower carbon footprint compared to virgin rigid plastics.